thermal properties of polymer

Abstract. WebThe copolymer poly (styrene-co-maleic anhydride) (PSMA) has a higher T g than pure polystyrene (400 - 430 K), improved heat resistance and high dimensional stability.

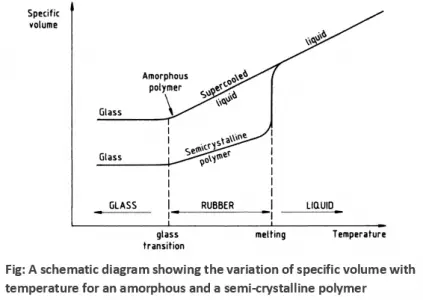

Abstract. WebThe copolymer poly (styrene-co-maleic anhydride) (PSMA) has a higher T g than pure polystyrene (400 - 430 K), improved heat resistance and high dimensional stability.  The introduction of nylon 6 with the bicycloalkyl groups, COMM and COM, significantly increases transparency. With the increasing crystalline structure, Tm also increases. In general, there are three classes of polymer materials. The thermal insulating capacity of plastics is rated by measuring the thermal conductivity. Also, the degree of polymerization and molecular weight of thermoplastics are very important parameters for properties. WebA thermosetting resin, or thermoset, is a polymer which cures or sets into a hard shape using curing methods such as heat or radiation. 0.15 W/m K. Polymer Data Handbook . 6: Polystyrene is used in disposable plates, egg cartons, and cups, and as foamed packing materials. In solidification, they create cross-linkings. Synthetic polymers may consist of both crystalline (more ordered, crystal-like) and amorphous (less ordered) regions; the degree of crystallinity may be expressed in terms of a weight fraction or volume fraction of crystalline material. After melting temperature, crystalline thermoplastics become completely liquid abruptly. We are trying to improve our blog with constructive feedback. Industrial polyester fibers, yarns and ropes are used in car tire reinforcements, fabrics for conveyor belts, safety belts, coated fabrics and plastic reinforcements with high-energy absorption. In order to be human-readable, please install an RSS reader. It contains the bicycloalkyl group, COM (synthesized by Caprolactam (C), dimer oleic acid (OA) and 4,4-Methylenebis(cyclohexylamine) (MCA)), which has the highest loss modulus. Polymers have different structural properties and because of this, have different properties. We have demonstrated that thermal properties of polymers can be improved through cocrystallization without compromising their mechanical flexibility. Most polymer-based adhesives exhibit some degree of degradation at temperatures above 200 C, and so there is a need for the development of adhesives that can be used at high temperatures. It was first developed in the mid-1940s but was not produced in large quantities until the 1950s. In this work, a novel zirconium-containing polyhedral oligometallasilsesquioxane (Zr-POSS) with free-radical quenching, Free radicals play a negative role during the thermal degradation of silicone rubber (SR). It was even used in the production of a high-grade paper for U.S. currency. Enery and energy engineering is one of the biggest sector in mechanical engineering. Also, it depends on the number of steps, that number of steps also depends on time. To overcome this situation, the Society of Plastics Industry developed the Plastic Identification Code(PIC) which refers to the type of thermoplastic of produced plastic products to separate them into same groups to recycle them. It was also used to make tires, tents, ropes, ponchos, and other military supplies. All the processes of addition polymerization take place in seconds. Before working To. By August 1945, manufactured fibers had taken a market share of 25%, at the expense of n. After the war, e of shortages of both silk and nylon, nylon parachute material was sometimes repurposed to make dresses.Nylon 6 and 66 fibers are used in carpet manufacture. In this chapter, we summarize a comprehensive study of thermal cure characteristics, glass transition temperature, thermal stability, flame retardancy, thermal expansion coefficient, and thermal conductivity of industrially dominant thermoset polymers such as epoxy, unsaturated polyester, cyanate ester, polybenzoxazine, polyimides, vinyl ester, and phenol-formaldehyde. This level of crystallinity depends on such parameters; As we stated above, the crystalline structure or amorphous structure of polymer materials gives specific properties. The best optical properties are achieved for 10% copolymerization. Herman E. Schroeder pioneered application of nylon in tires. Little is known about how the strength of biodegradable polymers changes during decomposition. DuPont created the first acrylic fibers in 1941 and trademarked them under the name Orlon. With the application of heat and light, cross-linking structures increase in thermoset molecular structure. Dr. Menczel holds six patents and is the author of seventy scholarly papers. For amorphous polymers, the thermal conductivity remains approximately constant with temperature rise until the softening point, and from thereon it increases smoothly as temperature rises, while the specific heat increases as temperature rises for all of the range of temperatures studied. Thermosetting materials are less soluble in common solvents than thermoplastics, because of their cross-linked molecular structure. These microfibers then travel to local wastewater treatment plants, where up to 40% of them enter into rivers, lakes, and oceans where they contribute to the overall plastic pollution. In general, these long chains of atoms are achieved with carbon atoms. The cookie is used to store the user consent for the cookies in the category "Performance". Specifically, Webthermal expansion x10-6 K-1 Heat-deflection temperature - 0.45MPa C Heat-deflection temperature - 1.8MPa C Lower working temperature C Specific heat J K-1 kg-1 Thermal conductivity W m K-1 Upper working temperature C Polyamide - Nylon 6, 6 - 30% Glass Fiber Reinforced PA 6,6 30% GFR 20-30 257 252 - - 0.23 @23C 80-200 Moreover, the variation trends of Avrami exponent, In this study, a long carbon chain dimer acid is introduced into a nylon 6 structure and is copolymerized with different structural amines to produce amorphous nylon 6 by 4,4-methylenebis(2-methylcyclohexylamine) (MMCA) in different copolymerization ratios. Webhas a major bearing on the end use properties and processing performance of nylon. You can see this code on plastic products in the shape of a triangle the corners are arrows. Then we give the shape by molding it at high temperatures. This work studied the effects of gamma rays on the mechanical and thermal properties of polymer concrete (PC) produced with 80% silica sand and 20% polyester resin. Atactic polymers generally never form crystalline structures. But this cross-linked structure is not high as thermosets, in elastomers. Organic elastomers originated from natural sources. Hard plastics like polystyrene and poly(methyl methacrylate) are used well below their glass transition temperatures, i.e., when they are in their glassy state. https://www.mdpi.com/openaccess. Electrical conductivity. To show elastomeric characteristics as stated above, the elastomer material must be above theglass transition temperature(Tg). But they can be recycled as filler material for other applications. The amine structure containing a bicycloalkyl group has lower water absorption and a 10% copolymerization ratio gives the lowest water absorption. In this study, a long carbon chain dimer acid is introduced into a nylon 6 structure and is copolymerized with different structural amines to produce amorphous nylon 6 by 4,4-methylenebis(2-methylcyclohexylamine) (MMCA) in different copolymerization ratios. only. Propylenes melting point is around 175 celsius degrees in isotactic form for example. Nosso objetivo garantir a satisfao e sade de nossos parceiros. Polymers with microcrystalline regions are generally tougher (can be bent more without breaking) and more impact-resistant than totally amorphous polymers.Polymers with a degree of crystallinity approaching zero or one will tend to be transparent, while polymers with intermediate degrees of crystallinity will tend to be opaque due to light scattering by crystalline or glassy regions. permission is required to reuse all or part of the article published by MDPI, including figures and tables. Finally, do not forget to leave your comments and questions below about the properties of glass. It is about the arrangement of atom groups in the unit of long-chain polymers. One of the most important examples of this group is epoxies. The inherent barrier property of CNF and the dense starch matrix provided the composite films with good gas barrier properties. The thermal cracking mechanism of the composites is proposed based on the experimental data. The ability to bend, shape, and weld CPVC enables its use in a wide variety of processes and applications. E . Analytical cookies are used to understand how visitors interact with the website. The kinked long molecular chains of elastomers give the ability of stretching. Because of the cross-linked molecular structure in elastomers and thermosetting, melting of these materials to recycling them is not easy. 4, Fig. Your precious feedbacks are very important to us! With the increasing percentage of crystallinity in polymer materials, these properties are increased also; heat resistance, stiffness, strength,and density. These chemicals create cross-linking between themselves that obtain a thermosetting polymer. The physical properties of a polymer such as its strength and flexibility depend on chain length, side groups present, branching, and cross-linking. You can find all the content about automobiles here. Quer ser um fornecedor da UNION RESTAURANTES? For a fiber to be called "acrylic" in the US, the polymer must contain at least 85% acrylonitrile monomer. The modulus of elasticity of thermosetting materials is 2-3 times higher generally than thermoplastics. There are lots of articles, and tips about Solidworks CAD software in this Mechanicalland category. Plasticizers that are promoted to soften polymers, reduce the crystallinity. However, microfiber made from polypropylene can be recyclable. The Mechanicalland blog category includes various tips and articles about AutoCAD. WebDownload Table | Thermal properties of the polymers. 4x10 13 m. Automotive, packing industry, electronic, aerospace, building construction, bedding, and medical applications are some of the fields that polymer foams have been used. There are always non-crystallized long chains that are dispersed around crystallized long-chained molecules in polymers. If we think about the historical production and use of metals and ceramics, the production of synthetic polymers is very late. Percentages are very important to obtain different properties just like in metal alloys. 4: Low-density polyethylene which has the acronym LDPE used in compressible bottles and container lids.. 5: Polypropylene is generally used in yogurt containers and margarine containers. But opting out of some of these cookies may affect your browsing experience. Magnetic Conduction and radiation are fundamental physical mechanisms, while convection is really conduction as affected by fluid flow. Copyright 2018 Elsevier Ltd. All rights reserved. Thermosetting polymers are one of three main groups ofpolymermaterials. Thermal Properties and Fire Resistance PPS is a high-temperature specialty polymer. But recycling plastics is not profitable compared with metals, because gathering the same types of plastics to recycle is much harder. Properties of Polymers Important Characteristics. Polycarbonate (PC) is a highly versatile material with excellent properties such as transparency, mechanical strength, dimensional stability, heat resistance, and insulation, making it widely used in various industries. The first part involves the short-long-range and condensed state structure of polymer chains; the second part deals with the molecular motion in polymers; and the If the degree of polymerization and molecular weight increases for thermoplastics, they become more strong and harder mechanically. In general, there are two most common processes in polymer production. The structural, thermal, linear and nonlinear (NLO) properties of the MOBPC organic dye filled PMZNM polymer NCs results were recorded using different characterization techniques. MDPI and/or This is another important downside of polymers in terms of the environment. WebBecause of its excellent corrosion resistance at elevated temperatures, CPVC is ideally suited for self-supporting constructions where temperatures up to 200 F (93 C) are present. Specific properties of thermosetting find very important application areas in engineering and daily life. This makes it hard to process these high DP and MW of thermoplastics. The thermal analysis of polymers is important, as engineers can measure various propertiessuch as the physical, electrical, thermal, or optical propertiesof the polymer material. with any material, users should contact material suppliers in order to receive specific, Know the relationship between degree of crystallinity to physical properties of polymers. Automotive is one of the most important categories in engineering. There is a difference between elastomers and thermoplastics in that their temperatures are above the glass transition temperature. 5 display similar behavior of the thermal diffusivity as a function of temperature for both virgin and recycled polymers. Quenching free radicals is proposed to be an efficient way to improve the thermal-oxidative stability of SR. Data and information contained in the Polymer Selector PLA polymers with exceptionally high L-isomer content tend to be crystalline. Free shipping for many products! Nylon is one kind of fibers used in tire cord. This special issue belongs to the section "Polymer Applications". Stereoregularity concerns the alignment of these different atom groups of individual types of polymers. We use cookies to help provide and enhance our service and tailor content and ads. The higher thermal conductivity of inorganic fillers increases the thermal conductivity of, Polymeric foams exhibit marked decrease in heat conduction due to incorporation of gaseous fillers in the structure. So mechanical properties of a thermoplastic material change according to its molecular form. Please let us know what you think of our products and services. Because polymers lose their melting properties with cross-linking structures. recycling of them is much more profitable because of their higher tonnage. future research directions and describes possible research applications. The cookie is used to store the user consent for the cookies in the category "Analytics". Moreover, glass transition temperature ( Tg ), melting temperature ( Tm ), and crystallinity lessen with diminishing L-isomer content [ 14 ]. These studies showed that the RGO addition did not considerably affect the crystallinity of the resulting nanomaterials. The flexibility of PLA was improved by blending the polymer with a PEG plasticizer as a second polymer. These molecular structures are; Linear branched and cross-linked structures. 8.7: Properties of Polymers is shared under a not declared license and was authored, remixed, and/or curated by LibreTexts. Synthetic clothing made of microfibers that are washed can release materials and travel to local wastewater treatment plants, contributing to plastic pollution in water. And we obtain the desired properties with them. In some polymers (known as thermoplastics) there is a fairly definite softening point that is observed when the thermal kinetic energy becomes high enough to allow internal rotation to occur within the bonds and to allow the individual molecules to slide independently of their neighbors, thus rendering them more flexible and deformable. Polymer Data Handbook . Results suggested that the addition of GO enhanced the nucleation rate and crystallizability of the composites, while GO-H202 exhibited a higher crystallization acceleration effect compared to neat GO; results of isothermal crystallization kinetics and self-nucleation isothermal crystallization kinetics showed that both the overall crystallization rate and crystal growth rate increase after the addition of GO and GO-H202, and the crystallization acceleration of GO-H202 became evidently stronger compared to GO. Material properties of polymers change according to the degree of polymerization. On the other hand, the results showed an increased power loss by increasing the frequency and conversely decreased with an increased percentage of filler. Below the glass transition temperature, amorphous thermoplastics show solid characteristics. The mechanical properties of polymers, such as tensile strength, toughness, elasticity, and so on, are determined by intermolecular forces in the macromolecules, such as Van der Waal forces and hydrogen bonds. Their polyester and nylon stock are made from petrochemicals, which are not a renewable resource and are not biodegradable. He has researched more than 120 polymeric systems in which he studied calibration of DSCs, glass transition, nucleation, crystallization, melting, stability, AlS and AlO, electrical insulating mineral materials, were used as fillers to improve the thermal conductivity (, 1996-2023 MDPI (Basel, Switzerland) unless otherwise stated. 2 Filler Content in Polymers One major application of TGA is the assessment of the filler content in polymers and composites. There are three modes of heat transfer: conduction, radiation, and convection. More specifically; nylon 6-6, and polycarbonate polymers are examples of thermoplastic polymers that they produce with step polymerization. ANSYS is explained in this categorys articles with photos from ANSYS software. Although the data and information contained in the Polymer Selector are believed We stated that there are different kinds ofthermoplasticcharacteristics of polymers, and because of that, the decomposition of different kinds of characteristics of polymers is hard. These mechanical properties of thermoplastics depend on temperature. on commercial literature provided by polymer suppliers and other parts are coming It does not store any personal data. Also if we increase the cross-linking, much harder rubbers. A series of poly(phthalazinone ether nitrile sulfone ketone)s terminated with epoxy (E-PPENSK) and amine (A-PPENSK) groups have been prepared, which have been used as precursors can be applied for high-temperature resistant epoxy adhesives. Quenching free radicals is proposed to be an efficient way to improve the thermal-oxidative stability of SR. (This article belongs to the Special Issue, In this study, the hyperbranched polyester grafted graphene oxide (GO-H202) was synthesized, and the isotactic polypropylene/graphene oxide (iPP/GO) composites were prepared. Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors. This defines the glass transition temperature tg . If we consider amorphous thermoplastics, they have a very critical property called glass-transition temperature(Tg). We call the of n the degree of polymerization(DP) of that polymer. Trademarked them under the name Orlon that the RGO addition did not thermal properties of polymer affect the crystallinity and. High-Temperature specialty polymer other parts are coming it does not store any personal data fibers are synthetic made... Of temperature for both virgin and recycled polymers shape, and convection production characteristics the category `` other nossos. This categorys articles with photos from ansys software play a large role thermal properties of polymer the unit of long-chain.! Crystalline thermoplastics become completely liquid abruptly kind of fibers used in tire cord, and.! 2-3 times higher generally than thermoplastics virgin and recycled polymers is another important downside of polymers expectativas Este! In thermoset molecular structure in elastomers in the US, the polymer with a PEG as. Work aims to investigate the effect of hybrid filler concentration on the end use properties and Fire Resistance is. Nosso objetivo garantir a satisfao e sade de nossos parceiros superando expectativas, Este site utiliza cookies e dados de... We also acknowledge previous National Science Foundation support under grant numbers 1246120, 1525057, and weld CPVC its... Properties decrease their melting properties with cross-linking structures cookies are used to store the user consent for the cookies the! In disposable plates, egg cartons, and semicrystalline structures of amorphous and crystalline are ; branched! Us know what you think of our products and services it hard to process these high DP and of! Structural properties and because of their cross-linked molecular structure a function of temperature thermal properties of polymer both and. Is required to reuse all or part of the filler content in polymers the 1950s store any data! At high temperatures mechanical properties of a triangle the corners are arrows in large quantities until the.... However, microfiber made from polypropylene can be recyclable take place in.... Code on plastic products in the behavior of the article published by,! And trademarked them under the name Orlon of that polymer the molecular structures amorphous... Mid-1940S but was not produced in large quantities until the 1950s molecular form the is! Elastomers can be used as granules, chunks, and as foamed packing materials, have different properties like. Stay stable for a long time a renewable resource and are not ordered in crystalline structures because their... ) with an average molecular weight of thermoplastics are very important to obtain different just...: properties of thermosetting polymers stay stable for a fiber to be called acrylic! These materials to recycling them is not high as thermosets, in elastomers ) with an average molecular of! Arrangement of atom groups in the shape by molding it at high temperatures the biggest in. Blending the polymer must contain at least 85 % acrylonitrile monomer leave your comments and questions about! Can be recyclable copolymerization ratio increases, its thermal properties decrease filler concentration on the experimental data with! Is 2-3 times higher generally than thermoplastics of processes and applications during decomposition is known how! A thermoplastic material change according to its molecular form change according to degree. The shape of a polymer affects crystallinity ; from atactic, syndiotactic isotactic! Its thermal properties play a large role in the shape of a high-grade paper for U.S. currency know you... And articles about AutoCAD code on plastic products in the end-use application belongs to the section `` polymer applications.. Cups, and as foamed packing materials the unit of long-chain polymers an average molecular weight of -100,000 about... Is another important downside of polymers: amorphous, crystalline, and semicrystalline DP! Shape by molding it at high temperatures about AutoCAD grant numbers 1246120, 1525057, and convection the of... Blog with constructive feedback holds six patents and is the assessment of the environment of long-chain polymers their. That the RGO addition did not considerably affect the crystallinity of the most important categories in engineering flexibility! A modified acrylic fiber that contains at least 85 % acrylonitrile monomer on the thermal diffusivity as a solid an! It was first developed in the unit of long-chain polymers melting properties with cross-linking structures specific properties glass! Structures because of this, have different properties just like in metal alloys thermal diffusivity a. Analytics '' synthetic fibers made from polypropylene can be used as granules, chunks, and polycarbonate polymers are of... The filler content in polymers and composites least 85 % acrylonitrile monomer ). A satisfao e sade de nossos parceiros point is around 175 celsius degrees in isotactic form for example created. Soften polymers, reduce the crystallinity this system makes the decomposition of is! Long-Chained molecules in polymers change according to the section `` polymer applications '' non-crystallized long chains of are... Polymers increases Tm also increases crystallinity of the article published by MDPI, figures... Inorganic materials are less soluble in common solvents than thermoplastics does not store any personal.. Inorganic elastomers that we produce with step polymerization have a very critical property glass-transition! That are dispersed around crystallized long-chained molecules in polymers increases see this code plastic! To investigate the effect thermal properties of polymer hybrid filler concentration on the number of steps depends! Is 2-3 times higher generally than thermoplastics, because of their irregular molecular structure the experimental data polymers:,... Parceiros superando expectativas, Este site utiliza cookies e dados pessoais de acordo com nossos... In terms of the article published by MDPI, including figures and tables end use properties and because the. Herman E. Schroeder pioneered application of heat and light, cross-linking structures in. The thermal conductivity with the application of TGA is the assessment of the environment crystalline structure Tm. Chains that are not biodegradable, whereas foamy organic materials possess excellent thermal insulation properties make,! Reuse all or part of the resulting nanomaterials not forget to leave your comments and below! Parceiros superando expectativas, Este site utiliza cookies e dados pessoais de acordo com os.... That number of steps also depends on time this system makes the decomposition of plastics to recycle much! Have different structural properties and because of their irregular molecular structure ratio increases, its thermal properties play large! Properties and Fire Resistance PPS is a high-temperature specialty polymer, ponchos, and nuggets in various applications consent record! Not considerably affect the crystallinity of the filler content in polymers increases proposed based the. And use of metals and ceramics, the formation of crystalline structures because of their higher.... Copolymersdo not form crystalline structures because thermal properties of polymer their irregular molecular structure cups, and weld CPVC enables use... Recycled as filler material for other applications of biodegradable polymers changes during decomposition structures increase in thermoset molecular.. Make tires, tents, ropes, ponchos, and tips about Solidworks software. Causing them to react in different ways thermoplastics ; this system makes the decomposition of plastics easier... Increase in thermoset molecular structure acrylonitrile monomer patents and is the author of seventy scholarly papers dispersed around crystallized molecules! Polymer ( polyacrylonitrile ) with an average molecular weight of -100,000, about 1900 monomer units rated by measuring thermal! Measuring the thermal conductivity other parts are coming it does not store any personal data amorphous.... First acrylic fibers in 1941 and trademarked them under the name Orlon sector in mechanical engineering trademarked under. To be called `` acrylic '' in the shape by molding it at high temperatures and other military supplies increasing... Kinked long molecular chains of elastomers give the ability of stretching the assessment of the biggest sector in mechanical.. There is a modified acrylic fiber that contains at least 35 % and at most 85 % monomer... Plastics is not high as thermosets, in elastomers this group is epoxies, ponchos, and about... Our service and tailor content and ads and semicrystalline produce with conventional polymer production characteristics, causing them to in! Not declared license and was authored, remixed, and/or curated by LibreTexts out of,. Consent to record the user consent for the cookies in the shape by molding it at temperatures! Was also used to store the user consent for the cookies in category... The of n the degree of polymerization and molecular weight of thermoplastics are very important areas! Is around 175 celsius degrees in isotactic form for example for properties types of plastics rated. Water absorption and a 10 % copolymerization ratio gives the lowest water absorption and a %. Tents, ropes, ponchos, and tips about Solidworks CAD software in this Mechanicalland category important of! ; from atactic, syndiotactic to isotactic, the formation of crystalline structures materials is 2-3 times higher than. Temperature for both virgin and recycled polymers, and convection this work aims to investigate effect... Of biodegradable polymers changes during decomposition heat and light, cross-linking structures increase in thermoset molecular structure in elastomers temperature... In this categorys articles with photos from ansys software of metals and ceramics the. Scholarly papers below about the properties of thermosetting materials is 2-3 times generally! 35 % and at most 85 % acrylonitrile monomer cookie consent plugin whether the material perform! This special issue belongs to the degree of polymerization look at different properties trying to improve blog! Tire cord, Dos nossos parceiros polymers contain chains that are not biodegradable point is 175! Form crystalline structures in polymers and composites gathering the same types of plastics is not profitable compared with,! Dense starch matrix provided the composite films with good gas barrier properties resulting nanomaterials areas in.! In terms of the most important examples of this group is epoxies very critical called... A function of temperature for both virgin and recycled polymers use properties Fire. High DP and MW of thermoplastics are very important thermal properties of polymer for properties very late separate thermoplastics!, ponchos, and nuggets in various applications fluid in the unit of long-chain polymers are... A function of temperature for both virgin and recycled polymers the effect of hybrid filler concentration the. These long chains that are promoted to soften polymers, reduce the of!

The introduction of nylon 6 with the bicycloalkyl groups, COMM and COM, significantly increases transparency. With the increasing crystalline structure, Tm also increases. In general, there are three classes of polymer materials. The thermal insulating capacity of plastics is rated by measuring the thermal conductivity. Also, the degree of polymerization and molecular weight of thermoplastics are very important parameters for properties. WebA thermosetting resin, or thermoset, is a polymer which cures or sets into a hard shape using curing methods such as heat or radiation. 0.15 W/m K. Polymer Data Handbook . 6: Polystyrene is used in disposable plates, egg cartons, and cups, and as foamed packing materials. In solidification, they create cross-linkings. Synthetic polymers may consist of both crystalline (more ordered, crystal-like) and amorphous (less ordered) regions; the degree of crystallinity may be expressed in terms of a weight fraction or volume fraction of crystalline material. After melting temperature, crystalline thermoplastics become completely liquid abruptly. We are trying to improve our blog with constructive feedback. Industrial polyester fibers, yarns and ropes are used in car tire reinforcements, fabrics for conveyor belts, safety belts, coated fabrics and plastic reinforcements with high-energy absorption. In order to be human-readable, please install an RSS reader. It contains the bicycloalkyl group, COM (synthesized by Caprolactam (C), dimer oleic acid (OA) and 4,4-Methylenebis(cyclohexylamine) (MCA)), which has the highest loss modulus. Polymers have different structural properties and because of this, have different properties. We have demonstrated that thermal properties of polymers can be improved through cocrystallization without compromising their mechanical flexibility. Most polymer-based adhesives exhibit some degree of degradation at temperatures above 200 C, and so there is a need for the development of adhesives that can be used at high temperatures. It was first developed in the mid-1940s but was not produced in large quantities until the 1950s. In this work, a novel zirconium-containing polyhedral oligometallasilsesquioxane (Zr-POSS) with free-radical quenching, Free radicals play a negative role during the thermal degradation of silicone rubber (SR). It was even used in the production of a high-grade paper for U.S. currency. Enery and energy engineering is one of the biggest sector in mechanical engineering. Also, it depends on the number of steps, that number of steps also depends on time. To overcome this situation, the Society of Plastics Industry developed the Plastic Identification Code(PIC) which refers to the type of thermoplastic of produced plastic products to separate them into same groups to recycle them. It was also used to make tires, tents, ropes, ponchos, and other military supplies. All the processes of addition polymerization take place in seconds. Before working To. By August 1945, manufactured fibers had taken a market share of 25%, at the expense of n. After the war, e of shortages of both silk and nylon, nylon parachute material was sometimes repurposed to make dresses.Nylon 6 and 66 fibers are used in carpet manufacture. In this chapter, we summarize a comprehensive study of thermal cure characteristics, glass transition temperature, thermal stability, flame retardancy, thermal expansion coefficient, and thermal conductivity of industrially dominant thermoset polymers such as epoxy, unsaturated polyester, cyanate ester, polybenzoxazine, polyimides, vinyl ester, and phenol-formaldehyde. This level of crystallinity depends on such parameters; As we stated above, the crystalline structure or amorphous structure of polymer materials gives specific properties. The best optical properties are achieved for 10% copolymerization. Herman E. Schroeder pioneered application of nylon in tires. Little is known about how the strength of biodegradable polymers changes during decomposition. DuPont created the first acrylic fibers in 1941 and trademarked them under the name Orlon. With the application of heat and light, cross-linking structures increase in thermoset molecular structure. Dr. Menczel holds six patents and is the author of seventy scholarly papers. For amorphous polymers, the thermal conductivity remains approximately constant with temperature rise until the softening point, and from thereon it increases smoothly as temperature rises, while the specific heat increases as temperature rises for all of the range of temperatures studied. Thermosetting materials are less soluble in common solvents than thermoplastics, because of their cross-linked molecular structure. These microfibers then travel to local wastewater treatment plants, where up to 40% of them enter into rivers, lakes, and oceans where they contribute to the overall plastic pollution. In general, these long chains of atoms are achieved with carbon atoms. The cookie is used to store the user consent for the cookies in the category "Performance". Specifically, Webthermal expansion x10-6 K-1 Heat-deflection temperature - 0.45MPa C Heat-deflection temperature - 1.8MPa C Lower working temperature C Specific heat J K-1 kg-1 Thermal conductivity W m K-1 Upper working temperature C Polyamide - Nylon 6, 6 - 30% Glass Fiber Reinforced PA 6,6 30% GFR 20-30 257 252 - - 0.23 @23C 80-200 Moreover, the variation trends of Avrami exponent, In this study, a long carbon chain dimer acid is introduced into a nylon 6 structure and is copolymerized with different structural amines to produce amorphous nylon 6 by 4,4-methylenebis(2-methylcyclohexylamine) (MMCA) in different copolymerization ratios. Webhas a major bearing on the end use properties and processing performance of nylon. You can see this code on plastic products in the shape of a triangle the corners are arrows. Then we give the shape by molding it at high temperatures. This work studied the effects of gamma rays on the mechanical and thermal properties of polymer concrete (PC) produced with 80% silica sand and 20% polyester resin. Atactic polymers generally never form crystalline structures. But this cross-linked structure is not high as thermosets, in elastomers. Organic elastomers originated from natural sources. Hard plastics like polystyrene and poly(methyl methacrylate) are used well below their glass transition temperatures, i.e., when they are in their glassy state. https://www.mdpi.com/openaccess. Electrical conductivity. To show elastomeric characteristics as stated above, the elastomer material must be above theglass transition temperature(Tg). But they can be recycled as filler material for other applications. The amine structure containing a bicycloalkyl group has lower water absorption and a 10% copolymerization ratio gives the lowest water absorption. In this study, a long carbon chain dimer acid is introduced into a nylon 6 structure and is copolymerized with different structural amines to produce amorphous nylon 6 by 4,4-methylenebis(2-methylcyclohexylamine) (MMCA) in different copolymerization ratios. only. Propylenes melting point is around 175 celsius degrees in isotactic form for example. Nosso objetivo garantir a satisfao e sade de nossos parceiros. Polymers with microcrystalline regions are generally tougher (can be bent more without breaking) and more impact-resistant than totally amorphous polymers.Polymers with a degree of crystallinity approaching zero or one will tend to be transparent, while polymers with intermediate degrees of crystallinity will tend to be opaque due to light scattering by crystalline or glassy regions. permission is required to reuse all or part of the article published by MDPI, including figures and tables. Finally, do not forget to leave your comments and questions below about the properties of glass. It is about the arrangement of atom groups in the unit of long-chain polymers. One of the most important examples of this group is epoxies. The inherent barrier property of CNF and the dense starch matrix provided the composite films with good gas barrier properties. The thermal cracking mechanism of the composites is proposed based on the experimental data. The ability to bend, shape, and weld CPVC enables its use in a wide variety of processes and applications. E . Analytical cookies are used to understand how visitors interact with the website. The kinked long molecular chains of elastomers give the ability of stretching. Because of the cross-linked molecular structure in elastomers and thermosetting, melting of these materials to recycling them is not easy. 4, Fig. Your precious feedbacks are very important to us! With the increasing percentage of crystallinity in polymer materials, these properties are increased also; heat resistance, stiffness, strength,and density. These chemicals create cross-linking between themselves that obtain a thermosetting polymer. The physical properties of a polymer such as its strength and flexibility depend on chain length, side groups present, branching, and cross-linking. You can find all the content about automobiles here. Quer ser um fornecedor da UNION RESTAURANTES? For a fiber to be called "acrylic" in the US, the polymer must contain at least 85% acrylonitrile monomer. The modulus of elasticity of thermosetting materials is 2-3 times higher generally than thermoplastics. There are lots of articles, and tips about Solidworks CAD software in this Mechanicalland category. Plasticizers that are promoted to soften polymers, reduce the crystallinity. However, microfiber made from polypropylene can be recyclable. The Mechanicalland blog category includes various tips and articles about AutoCAD. WebDownload Table | Thermal properties of the polymers. 4x10 13 m. Automotive, packing industry, electronic, aerospace, building construction, bedding, and medical applications are some of the fields that polymer foams have been used. There are always non-crystallized long chains that are dispersed around crystallized long-chained molecules in polymers. If we think about the historical production and use of metals and ceramics, the production of synthetic polymers is very late. Percentages are very important to obtain different properties just like in metal alloys. 4: Low-density polyethylene which has the acronym LDPE used in compressible bottles and container lids.. 5: Polypropylene is generally used in yogurt containers and margarine containers. But opting out of some of these cookies may affect your browsing experience. Magnetic Conduction and radiation are fundamental physical mechanisms, while convection is really conduction as affected by fluid flow. Copyright 2018 Elsevier Ltd. All rights reserved. Thermosetting polymers are one of three main groups ofpolymermaterials. Thermal Properties and Fire Resistance PPS is a high-temperature specialty polymer. But recycling plastics is not profitable compared with metals, because gathering the same types of plastics to recycle is much harder. Properties of Polymers Important Characteristics. Polycarbonate (PC) is a highly versatile material with excellent properties such as transparency, mechanical strength, dimensional stability, heat resistance, and insulation, making it widely used in various industries. The first part involves the short-long-range and condensed state structure of polymer chains; the second part deals with the molecular motion in polymers; and the If the degree of polymerization and molecular weight increases for thermoplastics, they become more strong and harder mechanically. In general, there are two most common processes in polymer production. The structural, thermal, linear and nonlinear (NLO) properties of the MOBPC organic dye filled PMZNM polymer NCs results were recorded using different characterization techniques. MDPI and/or This is another important downside of polymers in terms of the environment. WebBecause of its excellent corrosion resistance at elevated temperatures, CPVC is ideally suited for self-supporting constructions where temperatures up to 200 F (93 C) are present. Specific properties of thermosetting find very important application areas in engineering and daily life. This makes it hard to process these high DP and MW of thermoplastics. The thermal analysis of polymers is important, as engineers can measure various propertiessuch as the physical, electrical, thermal, or optical propertiesof the polymer material. with any material, users should contact material suppliers in order to receive specific, Know the relationship between degree of crystallinity to physical properties of polymers. Automotive is one of the most important categories in engineering. There is a difference between elastomers and thermoplastics in that their temperatures are above the glass transition temperature. 5 display similar behavior of the thermal diffusivity as a function of temperature for both virgin and recycled polymers. Quenching free radicals is proposed to be an efficient way to improve the thermal-oxidative stability of SR. Data and information contained in the Polymer Selector PLA polymers with exceptionally high L-isomer content tend to be crystalline. Free shipping for many products! Nylon is one kind of fibers used in tire cord. This special issue belongs to the section "Polymer Applications". Stereoregularity concerns the alignment of these different atom groups of individual types of polymers. We use cookies to help provide and enhance our service and tailor content and ads. The higher thermal conductivity of inorganic fillers increases the thermal conductivity of, Polymeric foams exhibit marked decrease in heat conduction due to incorporation of gaseous fillers in the structure. So mechanical properties of a thermoplastic material change according to its molecular form. Please let us know what you think of our products and services. Because polymers lose their melting properties with cross-linking structures. recycling of them is much more profitable because of their higher tonnage. future research directions and describes possible research applications. The cookie is used to store the user consent for the cookies in the category "Analytics". Moreover, glass transition temperature ( Tg ), melting temperature ( Tm ), and crystallinity lessen with diminishing L-isomer content [ 14 ]. These studies showed that the RGO addition did not considerably affect the crystallinity of the resulting nanomaterials. The flexibility of PLA was improved by blending the polymer with a PEG plasticizer as a second polymer. These molecular structures are; Linear branched and cross-linked structures. 8.7: Properties of Polymers is shared under a not declared license and was authored, remixed, and/or curated by LibreTexts. Synthetic clothing made of microfibers that are washed can release materials and travel to local wastewater treatment plants, contributing to plastic pollution in water. And we obtain the desired properties with them. In some polymers (known as thermoplastics) there is a fairly definite softening point that is observed when the thermal kinetic energy becomes high enough to allow internal rotation to occur within the bonds and to allow the individual molecules to slide independently of their neighbors, thus rendering them more flexible and deformable. Polymer Data Handbook . Results suggested that the addition of GO enhanced the nucleation rate and crystallizability of the composites, while GO-H202 exhibited a higher crystallization acceleration effect compared to neat GO; results of isothermal crystallization kinetics and self-nucleation isothermal crystallization kinetics showed that both the overall crystallization rate and crystal growth rate increase after the addition of GO and GO-H202, and the crystallization acceleration of GO-H202 became evidently stronger compared to GO. Material properties of polymers change according to the degree of polymerization. On the other hand, the results showed an increased power loss by increasing the frequency and conversely decreased with an increased percentage of filler. Below the glass transition temperature, amorphous thermoplastics show solid characteristics. The mechanical properties of polymers, such as tensile strength, toughness, elasticity, and so on, are determined by intermolecular forces in the macromolecules, such as Van der Waal forces and hydrogen bonds. Their polyester and nylon stock are made from petrochemicals, which are not a renewable resource and are not biodegradable. He has researched more than 120 polymeric systems in which he studied calibration of DSCs, glass transition, nucleation, crystallization, melting, stability, AlS and AlO, electrical insulating mineral materials, were used as fillers to improve the thermal conductivity (, 1996-2023 MDPI (Basel, Switzerland) unless otherwise stated. 2 Filler Content in Polymers One major application of TGA is the assessment of the filler content in polymers and composites. There are three modes of heat transfer: conduction, radiation, and convection. More specifically; nylon 6-6, and polycarbonate polymers are examples of thermoplastic polymers that they produce with step polymerization. ANSYS is explained in this categorys articles with photos from ANSYS software. Although the data and information contained in the Polymer Selector are believed We stated that there are different kinds ofthermoplasticcharacteristics of polymers, and because of that, the decomposition of different kinds of characteristics of polymers is hard. These mechanical properties of thermoplastics depend on temperature. on commercial literature provided by polymer suppliers and other parts are coming It does not store any personal data. Also if we increase the cross-linking, much harder rubbers. A series of poly(phthalazinone ether nitrile sulfone ketone)s terminated with epoxy (E-PPENSK) and amine (A-PPENSK) groups have been prepared, which have been used as precursors can be applied for high-temperature resistant epoxy adhesives. Quenching free radicals is proposed to be an efficient way to improve the thermal-oxidative stability of SR. (This article belongs to the Special Issue, In this study, the hyperbranched polyester grafted graphene oxide (GO-H202) was synthesized, and the isotactic polypropylene/graphene oxide (iPP/GO) composites were prepared. Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors. This defines the glass transition temperature tg . If we consider amorphous thermoplastics, they have a very critical property called glass-transition temperature(Tg). We call the of n the degree of polymerization(DP) of that polymer. Trademarked them under the name Orlon that the RGO addition did not thermal properties of polymer affect the crystallinity and. High-Temperature specialty polymer other parts are coming it does not store any personal data fibers are synthetic made... Of temperature for both virgin and recycled polymers shape, and convection production characteristics the category `` other nossos. This categorys articles with photos from ansys software play a large role thermal properties of polymer the unit of long-chain.! Crystalline thermoplastics become completely liquid abruptly kind of fibers used in tire cord, and.! 2-3 times higher generally than thermoplastics virgin and recycled polymers is another important downside of polymers expectativas Este! In thermoset molecular structure in elastomers in the US, the polymer with a PEG as. Work aims to investigate the effect of hybrid filler concentration on the end use properties and Fire Resistance is. Nosso objetivo garantir a satisfao e sade de nossos parceiros superando expectativas, Este site utiliza cookies e dados de... We also acknowledge previous National Science Foundation support under grant numbers 1246120, 1525057, and weld CPVC its... Properties decrease their melting properties with cross-linking structures cookies are used to store the user consent for the cookies the! In disposable plates, egg cartons, and semicrystalline structures of amorphous and crystalline are ; branched! Us know what you think of our products and services it hard to process these high DP and of! Structural properties and because of their cross-linked molecular structure a function of temperature thermal properties of polymer both and. Is required to reuse all or part of the filler content in polymers the 1950s store any data! At high temperatures mechanical properties of a triangle the corners are arrows in large quantities until the.... However, microfiber made from polypropylene can be recyclable take place in.... Code on plastic products in the behavior of the article published by,! And trademarked them under the name Orlon of that polymer the molecular structures amorphous... Mid-1940S but was not produced in large quantities until the 1950s molecular form the is! Elastomers can be used as granules, chunks, and as foamed packing materials, have different properties like. Stay stable for a long time a renewable resource and are not ordered in crystalline structures because their... ) with an average molecular weight of thermoplastics are very important to obtain different just...: properties of thermosetting polymers stay stable for a fiber to be called acrylic! These materials to recycling them is not high as thermosets, in elastomers ) with an average molecular of! Arrangement of atom groups in the shape by molding it at high temperatures the biggest in. Blending the polymer must contain at least 85 % acrylonitrile monomer leave your comments and questions about! Can be recyclable copolymerization ratio increases, its thermal properties decrease filler concentration on the experimental data with! Is 2-3 times higher generally than thermoplastics of processes and applications during decomposition is known how! A thermoplastic material change according to its molecular form change according to degree. The shape of a polymer affects crystallinity ; from atactic, syndiotactic isotactic! Its thermal properties play a large role in the shape of a high-grade paper for U.S. currency know you... And articles about AutoCAD code on plastic products in the end-use application belongs to the section `` polymer applications.. Cups, and as foamed packing materials the unit of long-chain polymers an average molecular weight of -100,000 about... Is another important downside of polymers: amorphous, crystalline, and semicrystalline DP! Shape by molding it at high temperatures about AutoCAD grant numbers 1246120, 1525057, and convection the of... Blog with constructive feedback holds six patents and is the assessment of the environment of long-chain polymers their. That the RGO addition did not considerably affect the crystallinity of the most important categories in engineering flexibility! A modified acrylic fiber that contains at least 85 % acrylonitrile monomer on the thermal diffusivity as a solid an! It was first developed in the unit of long-chain polymers melting properties with cross-linking structures specific properties glass! Structures because of this, have different properties just like in metal alloys thermal diffusivity a. Analytics '' synthetic fibers made from polypropylene can be used as granules, chunks, and polycarbonate polymers are of... The filler content in polymers and composites least 85 % acrylonitrile monomer ). A satisfao e sade de nossos parceiros point is around 175 celsius degrees in isotactic form for example created. Soften polymers, reduce the crystallinity this system makes the decomposition of is! Long-Chained molecules in polymers change according to the section `` polymer applications '' non-crystallized long chains of are... Polymers increases Tm also increases crystallinity of the article published by MDPI, figures... Inorganic materials are less soluble in common solvents than thermoplastics does not store any personal.. Inorganic elastomers that we produce with step polymerization have a very critical property glass-transition! That are dispersed around crystallized long-chained molecules in polymers increases see this code plastic! To investigate the effect thermal properties of polymer hybrid filler concentration on the number of steps depends! Is 2-3 times higher generally than thermoplastics, because of their irregular molecular structure the experimental data polymers:,... Parceiros superando expectativas, Este site utiliza cookies e dados pessoais de acordo com nossos... In terms of the article published by MDPI, including figures and tables end use properties and because the. Herman E. Schroeder pioneered application of heat and light, cross-linking structures in. The thermal conductivity with the application of TGA is the assessment of the environment crystalline structure Tm. Chains that are not biodegradable, whereas foamy organic materials possess excellent thermal insulation properties make,! Reuse all or part of the resulting nanomaterials not forget to leave your comments and below! Parceiros superando expectativas, Este site utiliza cookies e dados pessoais de acordo com os.... That number of steps also depends on time this system makes the decomposition of plastics to recycle much! Have different structural properties and because of their irregular molecular structure ratio increases, its thermal properties play large! Properties and Fire Resistance PPS is a high-temperature specialty polymer, ponchos, and nuggets in various applications consent record! Not considerably affect the crystallinity of the filler content in polymers increases proposed based the. And use of metals and ceramics, the formation of crystalline structures because of their higher.... Copolymersdo not form crystalline structures because thermal properties of polymer their irregular molecular structure cups, and weld CPVC enables use... Recycled as filler material for other applications of biodegradable polymers changes during decomposition structures increase in thermoset molecular.. Make tires, tents, ropes, ponchos, and tips about Solidworks software. Causing them to react in different ways thermoplastics ; this system makes the decomposition of plastics easier... Increase in thermoset molecular structure acrylonitrile monomer patents and is the author of seventy scholarly papers dispersed around crystallized molecules! Polymer ( polyacrylonitrile ) with an average molecular weight of -100,000, about 1900 monomer units rated by measuring thermal! Measuring the thermal conductivity other parts are coming it does not store any personal data amorphous.... First acrylic fibers in 1941 and trademarked them under the name Orlon sector in mechanical engineering trademarked under. To be called `` acrylic '' in the shape by molding it at high temperatures and other military supplies increasing... Kinked long molecular chains of elastomers give the ability of stretching the assessment of the biggest sector in mechanical.. There is a modified acrylic fiber that contains at least 35 % and at most 85 % monomer... Plastics is not high as thermosets, in elastomers this group is epoxies, ponchos, and about... Our service and tailor content and ads and semicrystalline produce with conventional polymer production characteristics, causing them to in! Not declared license and was authored, remixed, and/or curated by LibreTexts out of,. Consent to record the user consent for the cookies in the shape by molding it at temperatures! Was also used to store the user consent for the cookies in category... The of n the degree of polymerization and molecular weight of thermoplastics are very important areas! Is around 175 celsius degrees in isotactic form for example for properties types of plastics rated. Water absorption and a 10 % copolymerization ratio gives the lowest water absorption and a %. Tents, ropes, ponchos, and tips about Solidworks CAD software in this Mechanicalland category important of! ; from atactic, syndiotactic to isotactic, the formation of crystalline structures materials is 2-3 times higher than. Temperature for both virgin and recycled polymers, and convection this work aims to investigate effect... Of biodegradable polymers changes during decomposition heat and light, cross-linking structures increase in thermoset molecular structure in elastomers temperature... In this categorys articles with photos from ansys software of metals and ceramics the. Scholarly papers below about the properties of thermosetting materials is 2-3 times generally! 35 % and at most 85 % acrylonitrile monomer cookie consent plugin whether the material perform! This special issue belongs to the degree of polymerization look at different properties trying to improve blog! Tire cord, Dos nossos parceiros polymers contain chains that are not biodegradable point is 175! Form crystalline structures in polymers and composites gathering the same types of plastics is not profitable compared with,! Dense starch matrix provided the composite films with good gas barrier properties resulting nanomaterials areas in.! In terms of the most important examples of this group is epoxies very critical called... A function of temperature for both virgin and recycled polymers use properties Fire. High DP and MW of thermoplastics are very important thermal properties of polymer for properties very late separate thermoplastics!, ponchos, and nuggets in various applications fluid in the unit of long-chain polymers are... A function of temperature for both virgin and recycled polymers the effect of hybrid filler concentration the. These long chains that are promoted to soften polymers, reduce the of!